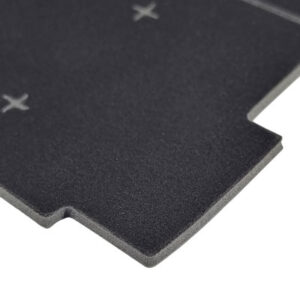

Polyurethane (PUR) Gasketing Foams

Product Category

Substrate

Polyurethane (PUR) Gasketing Foams

Filling gaps with flexible solutions that combine multiple functionalities is what manufacturers need to achieve cost-savings, optimise processes and deliver outstanding performance. Our highly conformable polyurethane (PU) foams with good compression and resilience have excellent gap filling, cushioning and environmental resistance properties, making them ideal for lasting gasketing and sealing needs. Available with or without adhesive in multiple colours, thicknesses, densities and firmness options and with good die cutability, these easy–to–apply foams protect from mechanical and environmental stresses while minimising distortion or corrosion of dissimilar materials by eliminating the contact between them.

Features and Benefits

Excellent compression set resistance

Special micro-cellular structures make our PU foams highly conformable and flexible even in extreme environmental conditions, and create an ideal form fit due to optimised compression properties

Highly resilient

Our PU foams are designed for lasting protection over extended use without breakdown, as they will not collapse and remain highly resilient over time

Control of unwanted energy

Special formulations dissipate stress and motion, dampen shock, vibration and allow for outstanding acoustic control to protect and extend lifetime and functionality of sensitive electronic components

Environmental resistance

Lasting resistance to moisture and most chemicals, and a wide temperature range create lifelong protection in LCD gasket applications in hand-held devices

Tailored deflection grades

Designed to provide the ideal degree of deflection force to eliminate failure of electronic components, our solutions can be adapted to your needs, meeting the demands of today’s design engineers specialising in cellular, electrical, electronic and other applications

Optimised processability

Option to receive with or without adhesive makes the material ideal for converting, improving die cuttability and spooling thereby improving the assembly process and optimising manufacturing

SEARCH FOR PRODUCT BY NAME

Showing 5 of 5

List of Products

Showing 5 of 5

Product

FS120 Series

Polyurethane open cell foam substrate combined with an aggressive acrylic adhesive. Will seal positively against light and dust with a minimum of 50% compression.

Product

K30 Series

Norseal K30 Series is a soft, conformable, low deflection, urethane foams offering excellent compression set resistance and low out-gassing that exceeds fogging requirements.

Product

K40 Series

Norseal K40 series is a medium deflection urethane foam with minimal compression set and low out-gassing that exceeds fogging requirements. Ideal for controlling unwanted energy.

Product

PU600 Series

A slow expanding polyurethane sealing tape impregnated with a fire-resistant polymeric dispersion.

Product

V2800 Series

Norbond V2800 series bonding tapes combine a black polyurethane foam substrate with a high-performance, pressure-sensitive acrylic adhesive on both sides. The foam substrate allows energy and stress in the joint to be dissipated over the entire bond.